Products Details

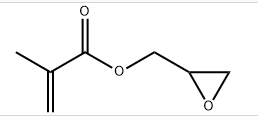

Glycidyl methacrylate 106-91-2 manufacturer

Introduction to the

Glycidylmethacrylate (GMA) is a monomer with both an acrylate double bond and an epoxy group. The double bond of acrylate has high reactivity, which can be self-polymerized and copolymerized with many other monomers. Epoxy groups can react with hydroxyl, amino, carboxyl or anhydride to introduce more functional groups, thus bringing more functionality to the product.

Therefore, GMA has an extremely wide range of applications in organic synthesis, polymer synthesis, polymer modification, composites, UV curable materials, coatings, adhesives, leather, chemical fiber paper, printing and dyeing, and many other aspects.

The physical and chemical properties

At room temperature, it is colorless, transparent and low viscosity liquid, soluble in common organic solvents, insoluble in water. There is usually a small amount of epichlorohydrin in the product due to the epichlorohydrin used in the manufacturing process.

GMA has the characteristic taste of acrylate and has a certain irritation on skin and eye contact. Both liquids and gases are flammable. Polymerization may occur at higher temperatures, so an inhibitor must be added.

Because methyl glycidyl ester of acrylic (GMA) molecules have lively vinyl and ionic reaction of epoxy groups of two functional groups, can be aggregated in functional way, also can with ion polymerization reaction way, therefore, can be used in the ethylene polymer type and condensation polymer modification, GMA can step in polymerization in three ways, one is the ethylene polymerization, the epoxy group on the branched chain, namely "O" type polymer; The second is an epoxy ring opening that allows the vinyl to sit on a branched chain, a "V" polymer. Third, compounds with active hydrogen react with GMA to open rings on the epoxy group to form chains. Using any of the above three methods, the polymer is modified during polymerization.

In terms of coatings, the addition of GMA can improve the hardness, gloss, adhesion and weather resistance of the coating film, which can be used for acrylic coatings, acrylic coatings, alkyd resin coatings, vinyl chloride resins and some waterborne coatings.

Chemical properties

Colorless liquid. The boiling point is 189℃, the relative density is 1.073 (25/4℃), the refractive index is 1.4494 and the flash point is 76℃. Soluble in organic solvents, insoluble in water.

use

1. Mainly used in powder coatings, also used in thermosetting coatings, fiber treating agents, adhesives, antistatic agents, vinyl chloride stabilizers, rubber and resin modifiers, ion exchange resins and printing ink binders.

2. It is mainly used for acrylic powder coating, latex coating, textile leather finishing agent, adhesive, medicine, etc

3. GMA, for short, is an important fine chemical raw material because it contains both carbon-carbon double bonds and epoxy groups in its molecules, which can carry out both free radical and ionic reactions. Therefore, it has high reactivity and can carry out different reactions respectively. Commonly used in acrylic and polyester decorative powder coatings, industrial and protective finishes, alkyd resins, adhesives, acrylic resin/emulsion synthesis, polyvinyl chloride based coatings, substitutes for hydrogenated LER, plastic modification, flame retardant materials, water absorbent materials, polymer capsules, cross-linked monomers and active diluents

Displaying 1 to 3 (of 6 products)